As a one-stop shop, Meraxis supplies its customers not only with raw materials, but also with machinery and tools. This means that even medium-sized companies can procure their investment goods globally through Meraxis.

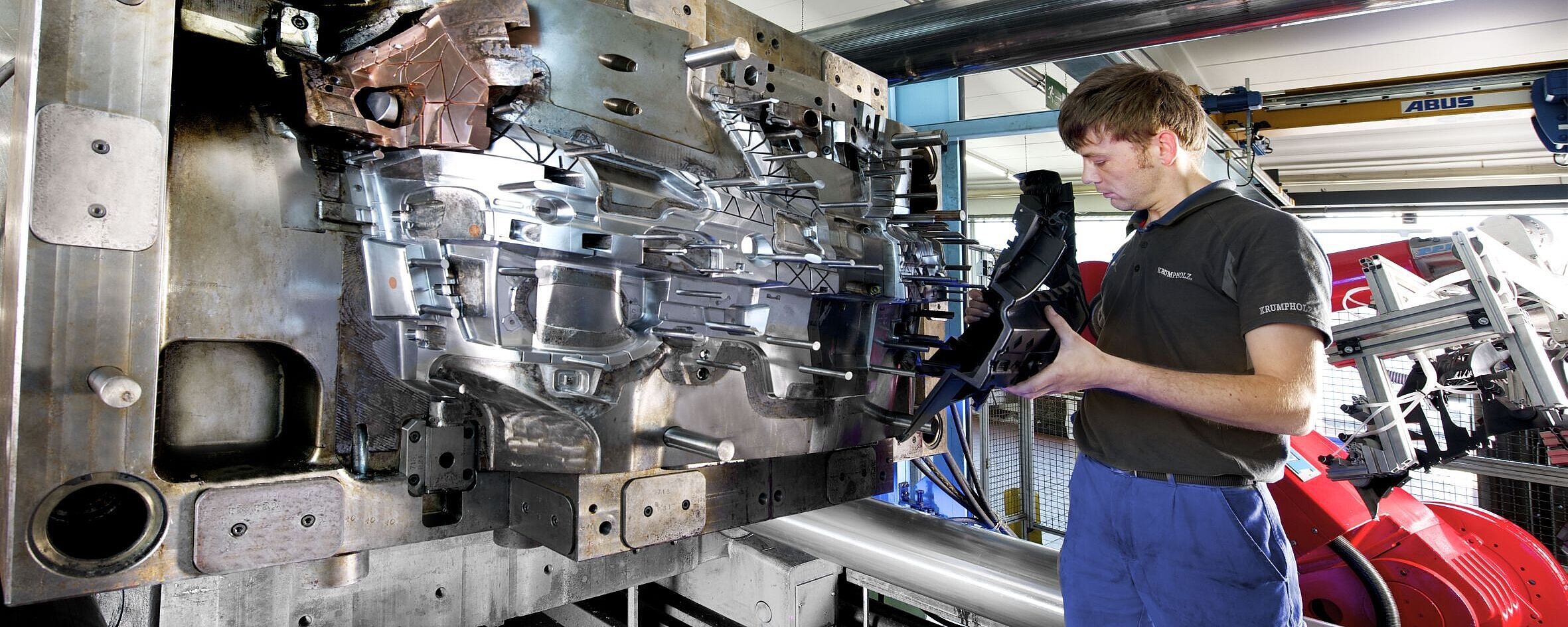

How exactly does this work? Our investment goods team procured three customised injection molding tools for the plastics technology and mold making specialist "Krumpholz Kunststofftechnik GmbH", located in Kronach, Germany.

Challenge

Krumpholz required three new injection molds for the production of the bumper of a new electric vehicle. The company deliberately wanted to procure the tools globally. Krumpholz selected Meraxis as a project partner with access to the global market. The distributor was contracted to manage the process up to the commissioning of the tools. Meraxis was also to coordinate the delivery logistics. Meraxis and Krumpholz jointly planned the technical support during the manufacturing process.

Lösung

Meraxis asked several suppliers worldwide, compared them and then selected the optimal solution together with Krumpholz. Suitable partners for tool production were found in China and Portugal. The toolmaking in China was supervised by Meraxis with their own team directly on site. During the entire process, all parties involved worked closely together and regularly exchanged information about the progress of the project. In this way, the partners were able to identify and eliminate any problems in production at an early stage.

Outcome

Meraxis accompanied the sampling of the tools before they were shipped to Krumpholz. Despite challenging times, when the global supply chains were severely affected by Corona and the blockade in the Suez Canal, Meraxis was able to sucessfully organize the logistics. To meet the schedule, the tooling from China was delivered to Germany by goods train; the two tools from Portugal came conventionally by sea. After the punctual delivery, the project entered the final and decisive phase: the tools went into operation on the machines. The first components were produced, which were precisely measured, tested and then fine-tuned once again. Thus, the release for serial production could take place.

Customer feedback

"The project went really well and professionally - for everyone involved. With Meraxis as our project partner, at no point did we have the feeling that we were putting work steps into the hands of external suppliers. The all-round support saved us an enormous amount of effort. We can definitely imagine using Meraxis for future tool procurements as well."

Steffen Rubenbauer, Operations Manager at Krumpholz Kunststofftechnnik